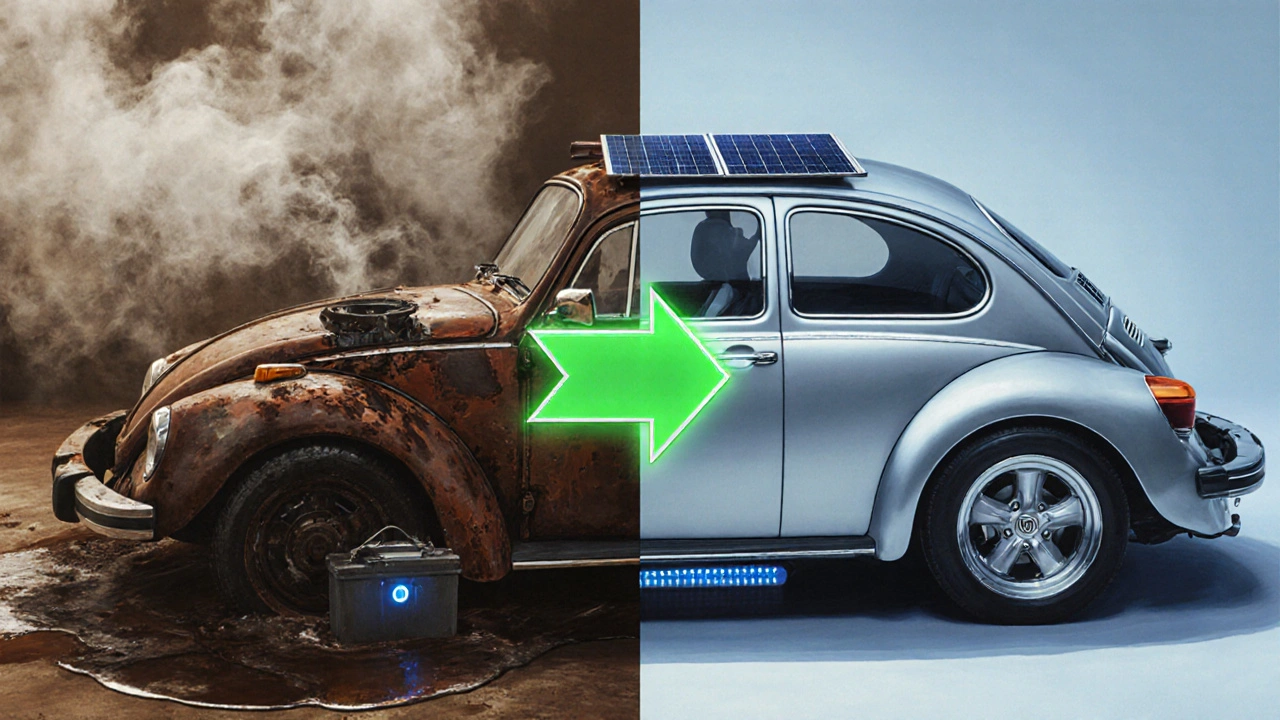

Imagine driving down the road in your old Honda Civic, but instead of the rumble of a gas engine, there’s silence. No fumes. No oil changes. Just smooth, instant torque and a charging cable plugged into your garage. This isn’t science fiction-it’s a real option for thousands of people in the UK and beyond. Converting a gas-powered car to electric isn’t just for hobbyists anymore. With battery prices falling and parts becoming more accessible, retrofitting your old car is now a practical, affordable way to go electric without buying new.

Why Convert Instead of Buy New?

Buying a new EV can cost £30,000 or more. Even used Teslas or Hyundai Kona EVs start around £20,000. But a 2005 Volkswagen Golf? You can pick one up for £2,000 in decent shape. Add a £8,000 conversion kit, and you’ve got a reliable, zero-emissions car for under £10,000. That’s a huge savings. Plus, you keep the car you love-the shape, the feel, the nostalgia. You’re not just reducing emissions; you’re giving a second life to something already built.

The UK government doesn’t offer direct grants for conversions yet, but you do avoid the £2,000 London Congestion Charge and the £140 annual Vehicle Excise Duty for petrol cars. Some local councils, like Bristol and Brighton, offer free parking for converted EVs. That’s real money saved over time.

What Cars Work Best for Conversion?

Not every gas car is a good candidate. You need something light, simple, and mechanically straightforward. The best candidates share these traits:

- Front-engine, rear-wheel-drive layout (easier to fit the motor and battery)

- Light weight (under 1,300 kg)

- Simple suspension and no complex electronics (no adaptive cruise, no drive-by-wire)

- Strong aftermarket support (parts are easy to find)

Popular choices include the Volkswagen Beetle (1970s-1990s), Fiat 500, Mazda MX-5 (first and second gen), and older Mini Coopers. Even the Ford Escort Mk2 and Renault 5 are common builds. Avoid heavy SUVs, luxury cars with complex CAN bus systems, or anything with turbochargers and automatic transmissions unless you’re an expert.

Why? Because you’re replacing the engine, fuel tank, exhaust, and radiator with a motor, battery pack, and cooling system. The simpler the original car, the less you have to fight.

The Core Components of an EV Conversion

Every conversion needs four main parts:

- Electric motor - Replaces the internal combustion engine. Most DIYers use AC induction or permanent magnet motors from EVs like the Nissan Leaf or Tesla Model S. Power ranges from 50 kW (70 hp) to 120 kW (160 hp).

- Battery pack - Usually made from recycled Tesla or Nissan Leaf cells. A typical setup uses 20-30 kWh of capacity, giving you 100-150 miles of range. Lithium-ion is standard; lead-acid is outdated and too heavy.

- Controller - The brain. It manages how much power goes to the motor based on your pedal input. Companies like EV Conversion Kits UK and EV West sell plug-and-play units.

- Charging system - A 7 kW onboard charger lets you plug into a home wallbox. You can also add a 22 kW fast-charging option if you’re upgrading.

You’ll also need a new radiator (for motor and battery cooling), a DC-DC converter (to power 12V systems like lights and radio), and a custom mounting frame for the battery. Most people remove the gas tank, fuel lines, and exhaust system entirely.

How Much Does It Cost?

Prices vary wildly depending on how much you do yourself. Here’s a realistic breakdown for a mid-range conversion in 2025:

| Component | Cost Range | Notes |

|---|---|---|

| Electric motor | £1,500-£4,000 | Used Nissan Leaf motor is popular and reliable |

| Battery pack (25 kWh) | £4,500-£7,000 | Recycled Tesla or Leaf cells; new packs cost double |

| Controller and inverter | £1,200-£2,500 | Plug-and-play units simplify installation |

| Charger (7 kW) | £600-£1,200 | Includes wiring and safety systems |

| Mounting hardware, cooling, wiring | £1,000-£2,000 | Custom fabrication and labour |

| Labour (if outsourced) | £2,000-£5,000 | DIY saves thousands; professionals charge hourly |

| Total | £10,800-£21,700 | Excludes donor car cost |

If you do it yourself and source used parts, you can hit £10,000 total. If you hire a shop, expect £18,000-£25,000. That’s still cheaper than a new EV with similar range.

The Process: What Happens During a Conversion?

Here’s a real-world step-by-step, based on a 2003 Mini Cooper conversion done in Bristol:

- Strip the car - Remove engine, transmission, fuel tank, exhaust, radiator, and all related plumbing. Keep the chassis, suspension, and body.

- Build the battery tray - Weld a custom steel frame under the floor to hold 48 lithium-ion modules. Weight must be balanced for handling.

- Mount the motor - Bolt the motor to the original transmission housing (if keeping a single-speed gearbox) or use a direct-drive setup.

- Install controller and wiring - Route high-voltage cables away from moving parts. Add fuses, contactors, and a main disconnect switch.

- Fit the charger and DC-DC converter - Connect to the 12V system so lights, radio, and airbag still work.

- Test and tune - Use diagnostic tools to check motor response, battery balance, and cooling. Drive slowly at first.

- Get it certified - In the UK, you need an Individual Vehicle Approval (IVA) test. This checks brakes, lights, steering, and electrical safety. A certified EV garage can help you pass.

The whole process takes 80-150 hours for a skilled DIYer. If you’re new, plan for 6-12 months. Rushing leads to mistakes-and dangerous ones.

Legal and Safety Rules in the UK

Converting a car to electric is legal, but it’s not a free-for-all. The Driver and Vehicle Standards Agency (DVSA) requires you to pass an IVA test. This isn’t a simple MOT. You need to prove:

- High-voltage systems are properly insulated and shielded

- There’s a manual disconnect switch within reach of the driver

- The battery pack is secured and won’t shift in a crash

- Brakes are upgraded to handle the extra weight (EVs are heavier than gas cars)

- Warning labels are clearly visible

You’ll also need to update your V5C logbook to show it’s now an electric vehicle. Failure to do this means you can’t tax or insure the car legally.

Insurance is tricky. Companies like Adrian Flux and Hastings Direct now offer EV conversion policies, but you’ll need a certificate from the converter or garage showing the work was done to safety standards. Don’t try to insure it as a gas car-that’s fraud.

Real-World Results: What’s It Like to Drive?

One owner in Bath converted a 1999 Peugeot 206. He used a 70 kW motor and a 24 kWh battery. The car now does 0-60 mph in 8.5 seconds-faster than the original 1.6L petrol version. Range? 110 miles on a full charge. Charging takes 4 hours on a 7 kW home unit.

He says: “It’s quieter than my old phone. No vibration. No smell. I drive to work, do the school run, and even take weekend trips to the Cotswolds. I haven’t bought fuel in 18 months.”

Another driver in Cardiff converted her 1997 Honda Civic. She uses a Tesla Model S motor and a 40 kWh pack. She gets 160 miles and can charge at public stations using CCS. Her annual running cost? Under £150 for electricity. Her gas car used to cost £1,200 a year.

The biggest surprise? Reliability. Electric motors have one moving part. No belts, no spark plugs, no timing chains. Maintenance is just checking brake fluid and tire pressure.

Who Shouldn’t Try This?

Converting a car isn’t for everyone. Avoid it if:

- You’ve never worked on cars before

- You don’t have access to a garage with power, tools, and ventilation

- You need a daily driver immediately

- You’re planning to sell the car soon-resale value for conversions is still uncertain

- You want a long-range EV (over 250 miles)

It’s a project. It takes time, patience, and a willingness to learn. If you’re not ready for that, buy a used Nissan Leaf instead. But if you’re the kind of person who enjoys tinkering, solving puzzles, and reducing your carbon footprint one bolt at a time? This might be the most rewarding car project you ever do.

Where to Start

Here’s how to begin:

- Find a donor car-look on Facebook Marketplace, Gumtree, or local scrap yards. Pick one with no rust and good suspension.

- Join a community-The UK Electric Vehicle Conversion Group on Facebook has 12,000 members. Ask questions. See what others have done.

- Buy a kit-Companies like EV Conversion Kits UK and EV West offer complete packages with instructions.

- Take a course-The Centre for Alternative Technology in Wales runs weekend EV conversion workshops.

- Plan your budget and timeline-Don’t underestimate the cost or time.

There’s no rush. The first conversion takes longer than the second. By the time you’ve done one, you’ll know exactly what you want to improve next time.

Is it legal to convert a petrol car to electric in the UK?

Yes, it’s legal, but you must pass an Individual Vehicle Approval (IVA) test and update your V5C logbook to reflect the change. The DVSA requires proof that high-voltage systems are safe, batteries are secured, and brakes are upgraded for the extra weight.

How much range do converted EVs typically have?

Most DIY conversions use 20-40 kWh battery packs, giving 100-160 miles of real-world range. Range depends on driving style, weather, and vehicle weight. A lightweight Mini with a 25 kWh pack can easily hit 120 miles. Heavier cars or aggressive driving reduce that.

Can I use Tesla batteries in my conversion?

Yes, many converters use salvaged Tesla Model S or Model 3 cells because they’re high-capacity and reliable. But they’re expensive and require a battery management system (BMS) designed for Tesla chemistry. Recycled Nissan Leaf cells are cheaper and easier to work with for beginners.

How long does an EV conversion take?

A skilled DIYer can finish in 3-6 months working part-time. First-time builders often take 8-12 months. Professional shops complete conversions in 4-8 weeks, but charge £15,000-£25,000 including labour.

Do converted EVs need an MOT?

After passing the IVA test, your converted car will be treated like any other EV and must pass a standard MOT annually. The test checks brakes, lights, steering, tyres, and emissions-but since it’s electric, the emissions test is skipped. Electrical safety and battery integrity are checked during IVA, not MOT.

Can I charge a converted EV at public stations?

Yes, if you install a CCS or Type 2 charging port. Most conversions use a Type 2 socket, which works with 95% of UK public chargers. Fast chargers (50kW+) are compatible if your controller supports them. Always confirm your car’s maximum charge rate before plugging in.

Are converted EVs reliable?

Yes-often more reliable than gas cars. Electric motors have no moving parts besides the rotor. There’s no oil, no coolant leaks from the engine, no timing belts to snap. Maintenance is limited to brakes, tyres, suspension, and checking battery connections. Many converted cars have over 50,000 miles with zero motor failures.

Comments

mark nine

I did this to my 2001 Miata last year. 70kW motor, 24kWh Leaf cells. 110 miles range. Zero maintenance since. No more oil changes. Just charge and go. Best decision ever.

November 12, 2025 at 18:29

Tony Smith

It is, indeed, a most admirable endeavor, one which demonstrates not only technical acumen but also a profound commitment to environmental stewardship. One must, however, ensure that the conversion adheres to the highest standards of safety and regulatory compliance, lest one invite catastrophic failure or legal censure.

November 13, 2025 at 15:56

Rakesh Kumar

Brooooooo!!! I just saw this and my heart exploded!!! I have a 1998 Fiat 500 sitting in my backyard collecting dust since 2020!!! I’m doing this!!! I’m going to make it electric and drive it to Goa!!! I’m gonna be the first Indian with a retro electric Fiat!!!

November 13, 2025 at 22:01

Bill Castanier

The IVA process is non-negotiable. Failure to update the V5C renders the vehicle uninsured and illegal. Do not skip documentation. It is not optional.

November 14, 2025 at 23:41

Ronnie Kaye

So you’re telling me I can turn my dad’s rusted 1998 Civic into a silent speed demon for less than the price of a new iPhone? And you want me to just sit here and cry about it? I’m in. Let’s go.

November 15, 2025 at 21:52

Priyank Panchal

You people think this is easy? You don’t know what you’re doing. I’ve seen 3 conversions that caught fire because someone used a cheap BMS. Don’t be a dumbass. If you don’t know how to solder, buy a Leaf. End of story.

November 17, 2025 at 21:14

Ian Maggs

There is something profoundly poetic, isn't there? To take the relics of the internal combustion age-the clattering, smoky, oil-stained machines-and transform them into silent, clean, electric ghosts, gliding through the world without leaving a trace... Yet, we must ask: is this redemption, or merely a more elegant form of denial?

November 18, 2025 at 21:03

Michael Gradwell

If you're not rich enough to buy a Tesla, you shouldn't be driving at all. This is just a hobby for people who can't afford the real thing. Stop pretending you're green. You're just playing with batteries.

November 19, 2025 at 07:56